Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Maximize Efficiency with a Climbing Conveyor Belt in Chain and Conveyor Equipment:

2023-08-04

Introduction: Understanding the Importance of a Climbing Conveyor Belt in Chain and Conveyor Equipment

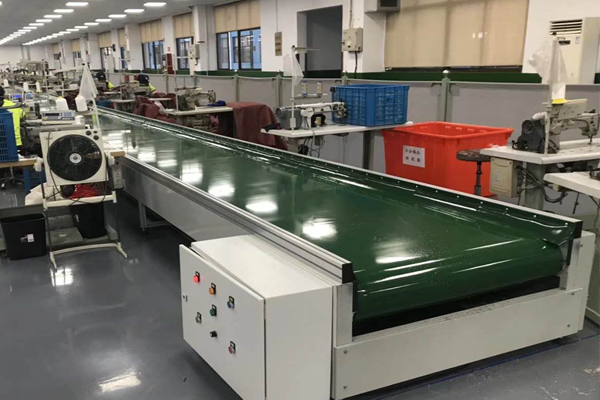

Climbing conveyor belts have emerged as an integral component in chain and conveyor equipment, playing a vital role in maximizing efficiency and productivity. These innovative belts offer a seamless and reliable solution for transporting materials vertically, providing a significant advantage in various industries. This article delves into the workings of climbing conveyor belts, their advantages, key applications, considerations for selection, and frequently asked questions. By the end, you'll have a comprehensive understanding of how this technology can revolutionize your operations.

How a Climbing Conveyor Belt Works: Exploring its Mechanism and Functionality

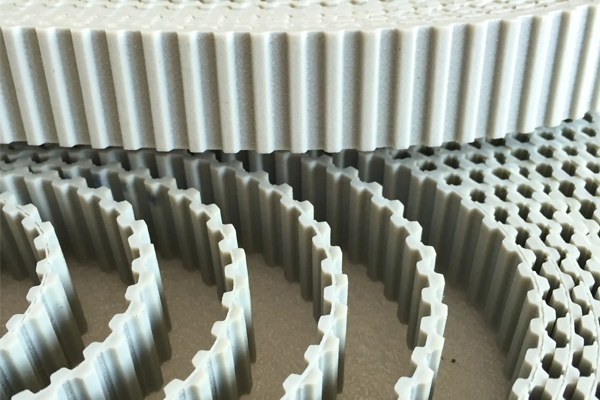

Climbing conveyor belts operate on a simple yet efficient mechanism that allows materials to be transported vertically with ease. These belts are equipped with specially designed cleats or flights that are strategically placed at regular intervals. The cleats ensure the material remains securely in place during the ascent, preventing any slippage or spillage.

The conveyor belt is driven by a motor and pulley system, which propels the belt forward. The incline and speed of the belt can be adjusted according to the requirements of the specific application. As the material reaches the top, it smoothly transitions onto the horizontal section of the conveyor belt, ready to be transported to the next stage of the process.

Advantages of a Climbing Conveyor Belt: Enhancing Efficiency and Productivity

1. Increased Vertical Transport Capacity: Climbing conveyor belts offer a significant advantage in scenarios where materials need to be transported vertically. They can efficiently transport heavy loads and bulk materials, optimizing the use of space and streamlining the workflow.

2. Reduced Manual Handling: By utilizing climbing conveyor belts, the need for manual handling of materials is minimized. This reduces the risk of injuries and improves overall safety in the workplace.

3. Improved Workflow: With climbing conveyor belts, the material flow can be effectively managed, ensuring a smooth and continuous workflow. This eliminates bottlenecks and enhances overall productivity.

4. Versatile Application: Climbing conveyor belts find application in a wide range of industries, including mining, construction, agriculture, and manufacturing. They can handle various materials such as ores, grains, aggregates, and packaged goods.

Key Applications of Climbing Conveyor Belts in Chain and Conveyor Equipment

1. Mining Industry: Climbing conveyor belts are extensively used in the mining industry for efficient transportation of coal, ore, and other minerals. They enable the vertical movement of materials in mines, optimizing the extraction process.

2. Construction Industry: In the construction industry, climbing conveyor belts are employed for vertical transportation of aggregates, sand, and concrete mixtures. This facilitates the seamless transfer of materials to higher levels, reducing manual labor and enhancing construction efficiency.

3. Agriculture Sector: Climbing conveyor belts are valuable in the agricultural sector for tasks such as loading and unloading bulk products, including grains, fertilizers, and animal feed. These belts enable the smooth vertical movement of materials, enabling efficient processing and storage.

Choosing the Right Climbing Conveyor Belt: Factors to Consider

When selecting a climbing conveyor belt for your chain and conveyor equipment, several factors should be taken into account:

1. Load Capacity: Determine the maximum weight the conveyor belt needs to handle and choose a belt that can withstand the load without compromising performance and safety.

2. Belt Material and Cleat Design: Consider the material composition of the belt and the design of the cleats to ensure they are suitable for the specific application. Factors such as abrasion resistance, flexibility, and grip should be considered.

3. Incline Angle and Speed: Assess the required incline angle and speed of the conveyor belt to ensure it aligns with the operational needs. Consult with experts to determine the optimal settings for maximum efficiency.

4. Maintenance and Durability: Evaluate the maintenance requirements and durability of the climbing conveyor belt. Choose a belt that is easy to maintain, with robust construction that can withstand the demands of your operations.

FAQs about Climbing Conveyor Belts in Chain and Conveyor Equipment

Q1: Can climbing conveyor belts handle fragile materials without causing damage?

A1: Yes, climbing conveyor belts can handle fragile materials by adjusting the speed and incline to ensure a gentle transport process.

Q2: Are climbing conveyor belts suitable for outdoor applications?

A2: Yes, climbing conveyor belts can be designed to withstand outdoor conditions with weather-resistant materials and protective measures.

Q3: Can climbing conveyor belts be integrated into existing chain and conveyor systems?

A3: Yes, climbing conveyor belts can be seamlessly integrated into existing systems, enhancing their vertical transport capabilities.

Q4: Do climbing conveyor belts require regular maintenance?

A4: Like any other conveyor belt, climbing conveyor belts require regular maintenance to ensure optimal performance and longevity.

Q5: Are climbing conveyor belts cost-effective?

A5: Climbing conveyor belts offer long-term cost savings by reducing manual labor, improving efficiency, and minimizing material spillage.

Conclusion: Leveraging the Power of Climbing Conveyor Belts for Optimal Efficiency

In a world where efficiency and productivity are paramount, climbing conveyor belts provide a game-changing solution for chain and conveyor equipment. By employing these innovative belts, industries can optimize their vertical material transport, reduce manual handling, enhance workflow, and improve overall efficiency. With their versatility and ability to handle various materials, climbing conveyor belts have become indispensable in mining, construction, agriculture, and manufacturing. Choose the right climbing conveyor belt for your operations, and unlock the full potential of your chain and conveyor equipment.

climbing conveyor belt

RELEVANT INFORMATION

7 installation tips for conveyor belts for coal mines

2022-07-01

524

Wire rope conveyor belt electric peeling machine

2022-07-01

24

What are the advantages of using flame retardant conveyor belts?

2022-07-01

75