Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

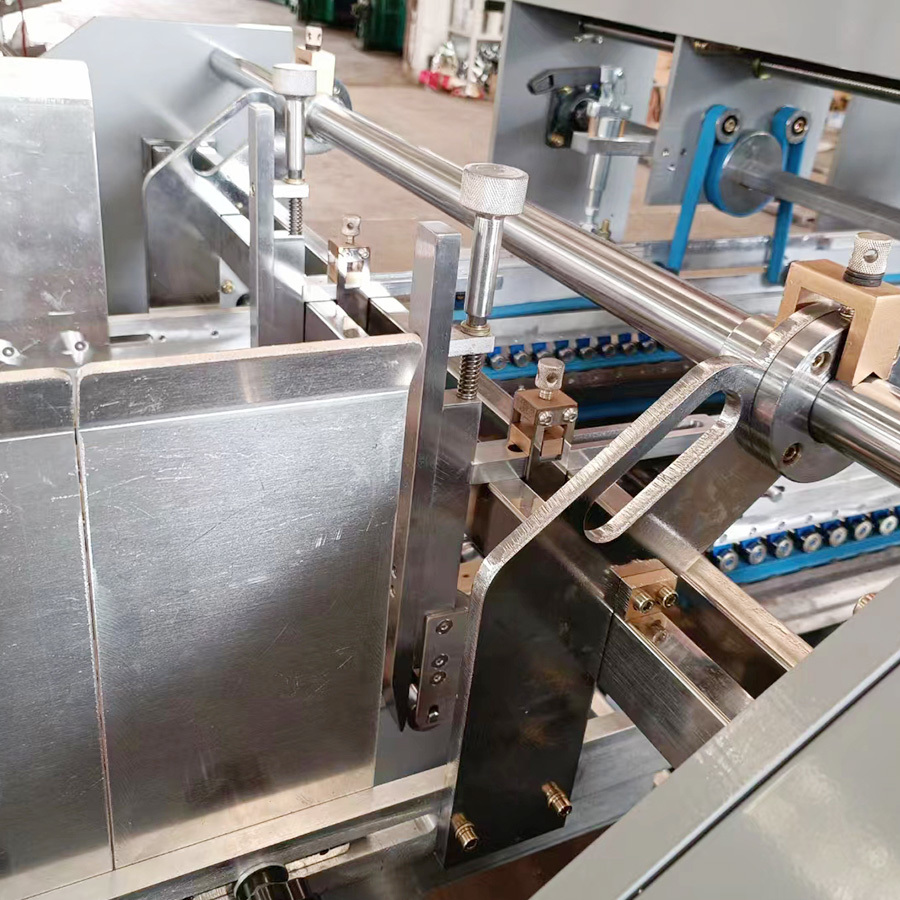

Product introduction

Paper feed unit:

·Servo control leading edge paper feeding increases suction flow, making paper feeding more stable and accurate.

·Variable frequency regulation of vacuum absorption air volume to match the size of paperboard; Set the continuous conveying and interval conveying functions.

·The straightening cots are double-layer glue, with soft inner layer and hard outer layer, which not only maintain the elasticity of the inner layer, but also

ensure the wear resistance of the surface, reducing the number of paperboard fed by flattening.

·Dust removal device: dust suction fan and dust removal brush remove paper scraps on the surface of cardboard. Multiple fans directly pump and add multiple rows of electrostatic brushes and rotary round brushes to further remove the dust on the surface of the cardboard.

·Set the order quantity, and automatically stop feeding after completion.

·The clearance between paper pullers and the position of left and right baffles are adjusted by computer control; The rear paper holder electrically controls the front and rear, speeding up the setting speed.

Previous:

ONLINE CONSULTING