Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Climbing Conveyor Belt: A Versatile Industrial Equipment for Efficient Material Handling

2023-08-04

Introduction:

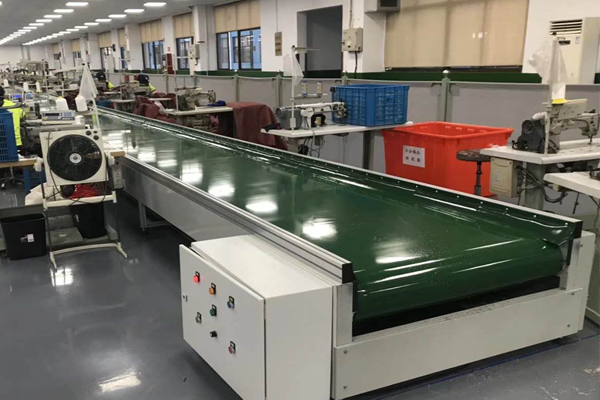

Climbing conveyor belts play an essential role in the industrial equipment and components sector, specifically within the chain and conveying systems. These innovative systems offer a versatile and efficient solution for material handling processes. In this article, we will delve into the concept of climbing conveyor belts and explore their applications across different industries.

1. What is a climbing conveyor belt?

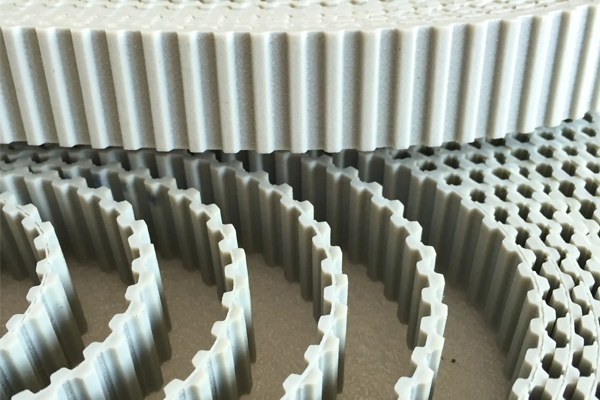

Climbing conveyor belts, also known as incline or vertical conveyors, are designed to transport materials vertically or at an inclined angle. Unlike traditional horizontal conveyors, climbing conveyor belts use specialized belts with cleats or buckets that enable them to move materials vertically or at steep angles. This unique design allows for seamless transportation of materials to higher levels or through challenging terrains.

2. How do climbing conveyor belts work?

Climbing conveyor belts rely on the principles of friction and gravity to move materials. The cleats or buckets on the belt provide the necessary grip to prevent slipping while the belt is in motion. The materials are loaded onto the conveyor belt at the lower end, and as the belt moves, the cleats or buckets carry the materials upward or along the desired incline. This efficient design minimizes the risk of material spillage and enhances the overall productivity of the material handling process.

3. Applications in various industries:

- Mining and Quarrying: Climbing conveyor belts are widely used in the mining and quarrying industry to transport ores, coal, stone, and other minerals vertically or at inclined angles. These belts facilitate the movement of materials in challenging terrains, reducing the need for manual labor and increasing operational efficiency.

- Agriculture: In the agricultural sector, climbing conveyor belts are utilized for tasks such as loading harvested crops onto trucks or transporting grains and feed to higher storage areas. The ability to move materials vertically or at inclined angles simplifies the logistics and enhances productivity in agricultural operations.

- Manufacturing and Packaging: Climbing conveyor belts find extensive use in manufacturing facilities and packaging industries. They are employed to transport products between different levels of production, ensuring a smooth flow of materials without the need for manual intervention.

- Construction: In the construction industry, climbing conveyor belts are used to efficiently transport construction materials such as sand, gravel, and concrete vertically or at inclined angles. This eliminates the need for manual labor-intensive processes, streamlining construction operations.

4. Benefits of climbing conveyor belts:

- Space Efficiency: Climbing conveyor belts utilize vertical space effectively, allowing for efficient material transportation in areas with limited horizontal space.

- Increased Productivity: The seamless movement of materials using climbing conveyor belts reduces the reliance on manual labor, leading to enhanced productivity and cost savings.

- Versatility: Climbing conveyor belts can handle a wide range of materials, including bulk solids, granules, and small items, making them suitable for various industries and applications.

- Safety: The cleats or buckets on climbing conveyor belts prevent material spillage, reducing the risk of accidents and ensuring a safe working environment.

In conclusion, climbing conveyor belts have revolutionized material handling processes in industries such as mining, agriculture, manufacturing, packaging, and construction. Their ability to transport materials vertically or at inclined angles offers versatility, efficiency, and space optimization. With their numerous benefits, climbing conveyor belts continue to play a crucial role in enhancing operational productivity and streamlining material transportation across diverse industrial sectors.

climbing conveyor belt

RELEVANT INFORMATION

7 installation tips for conveyor belts for coal mines

2022-07-01

524

Wire rope conveyor belt electric peeling machine

2022-07-01

24

What are the advantages of using flame retardant conveyor belts?

2022-07-01

75