Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The Benefits of Using a Climbing Conveyor Belt for Industrial Equipment

2023-08-05

1. Introduction

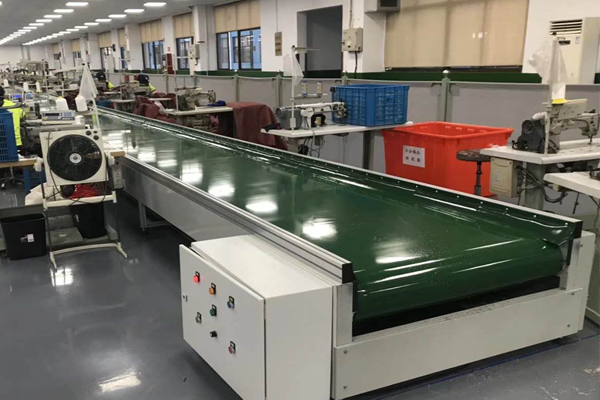

In today's fast-paced industrial landscape, optimizing efficiency and reducing operational costs are crucial for businesses to thrive. One innovative solution that has gained prominence is the climbing conveyor belt. This article explores the numerous benefits of incorporating a climbing conveyor belt into your industrial equipment setup and why it can be a game-changer for your business.

2. Enhanced Efficiency with a Climbing Conveyor Belt

A climbing conveyor belt offers significant improvements in efficiency compared to traditional conveyor systems. By utilizing vertical movement capabilities, it allows for seamless transportation of materials between different levels, eliminating the need for additional manual handling or transfers. This streamlines the production process, reduces downtime, and ultimately increases output.

2.1 Streamlined Material Handling

With a climbing conveyor belt, materials can be transported directly from one level to another without the need for manual intervention. This eliminates bottlenecks and minimizes the risk of material damage during transfers. The automated nature of the system ensures consistent and efficient movement of goods, enhancing overall productivity.

2.2 Continuous Flow of Production

By minimizing interruptions in the production line, a climbing conveyor belt helps maintain a continuous flow of materials. This is particularly beneficial in industries that require constant supply or rapid movement of goods. The smooth operation ensures timely delivery and reduces the likelihood of production delays.

3. Reduction in Labor Costs

Labor costs can significantly impact a business's bottom line. The implementation of a climbing conveyor belt can lead to substantial savings in this area.

3.1 Automation and Reduced Manual Labor

By automating the material handling process, a climbing conveyor belt reduces the need for manual labor. This translates to lower labor costs and provides an opportunity to reallocate human resources to more value-added tasks. Additionally, the system can operate continuously, eliminating the need for shift changes and further reducing labor expenses.

3.2 Increased Operational Efficiency

The enhanced efficiency achieved through a climbing conveyor belt results in higher production output with fewer labor resources. This allows businesses to optimize their workforce and potentially reduce staffing requirements, leading to significant cost savings over time.

4. Improved Safety Measures

Ensuring the safety of employees is a top priority for any business. A climbing conveyor belt offers several safety advantages over traditional conveyor systems.

4.1 Minimized Manual Handling Risks

Manual material handling can pose various risks to workers, including musculoskeletal injuries and accidents. With a climbing conveyor belt, the need for manual handling is greatly reduced, mitigating these risks and creating a safer working environment.

4.2 Enhanced Fall Protection

Climbing conveyor belts are equipped with advanced safety features, including guardrails and emergency stop systems. These mechanisms provide increased fall protection for workers operating near or using the conveyor system, reducing the likelihood of accidents and injuries.

5. Increased Flexibility and Adaptability

A climbing conveyor belt offers businesses greater flexibility and adaptability in their operations.

5.1 Vertical Transport Capability

The vertical transport capability of a climbing conveyor belt allows businesses to make the most of available space, optimizing their facility layout. This feature is particularly beneficial for industries with limited floor space, enabling efficient utilization of vertical height.

5.2 Customizable Configurations

Climbing conveyor belts can be customized to suit specific operational requirements. Whether it's adjusting the incline, speed, or integrating additional features, businesses can tailor the system to their unique needs. This flexibility ensures maximum efficiency and productivity while accommodating evolving business demands.

6. Versatile Applications of Climbing Conveyor Belts

Climbing conveyor belts find applications across various industries and sectors.

6.1 Manufacturing and Assembly

In manufacturing and assembly processes, climbing conveyor belts facilitate the seamless transportation of components and finished products between different stages of production. This improves workflow, reduces handling time, and supports lean manufacturing principles.

6.2 Warehousing and Distribution

In warehousing and distribution operations, climbing conveyor belts enable efficient movement of goods within multi-level storage facilities. They ensure smooth order fulfillment, minimize order picking errors, and enhance overall logistics operations.

6.3 Construction and Mining

The construction and mining industries benefit from climbing conveyor belts by enabling the vertical transport of materials, such as aggregates, ores, and construction debris. This eliminates the need for manual hauling, reducing operational costs and improving productivity in challenging work environments.

6.4 Agriculture and Farming

Climbing conveyor belts are also utilized in agriculture and farming to transport crops, grains, and livestock feed between different levels of storage or processing facilities. This helps streamline agricultural operations and promotes efficient supply chain management.

7. Frequently Asked Questions (FAQs)

Q1: How does a climbing conveyor belt differ from a traditional conveyor system?

A1: Unlike traditional conveyor systems, climbing conveyor belts have the ability to transport materials vertically between different levels, eliminating the need for additional transfers or manual handling.

Q2: Can a climbing conveyor belt be integrated into existing industrial equipment?

A2: Yes, climbing conveyor belts can be customized and integrated into existing industrial equipment setups, providing a seamless and efficient solution without major modifications.

Q3: Are climbing conveyor belts suitable for heavy-duty applications?

A3: Yes, climbing conveyor belts are designed to handle heavy loads and can be engineered to withstand demanding industrial environments.

Q4: What safety features should climbing conveyor belts have?

A4: Climbing conveyor belts should include safety features such as guardrails, emergency stop systems, and sensors to ensure worker safety and prevent accidents.

Q5: Can climbing conveyor belts improve operational efficiency in the long run?

A5: Yes, the enhanced efficiency, reduced labor costs, and improved safety measures offered by climbing conveyor belts can lead to long-term operational improvements and cost savings.

8. Conclusion

Incorporating a climbing conveyor belt into your industrial equipment setup can bring numerous benefits to your business. From increased efficiency and reduced labor costs to improved safety measures and enhanced flexibility, this innovative solution has the potential to revolutionize your operations. Embrace the advantages of a climbing conveyor belt and stay ahead in the competitive industrial landscape.

climbing conveyor belt

RELEVANT INFORMATION

7 installation tips for conveyor belts for coal mines

2022-07-01

524

Wire rope conveyor belt electric peeling machine

2022-07-01

24

What are the advantages of using flame retardant conveyor belts?

2022-07-01

75