Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Characteristics and importance of Teflon conveyor belt

2023-06-06

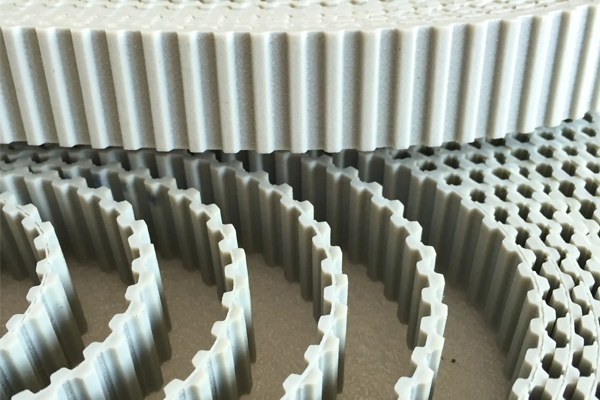

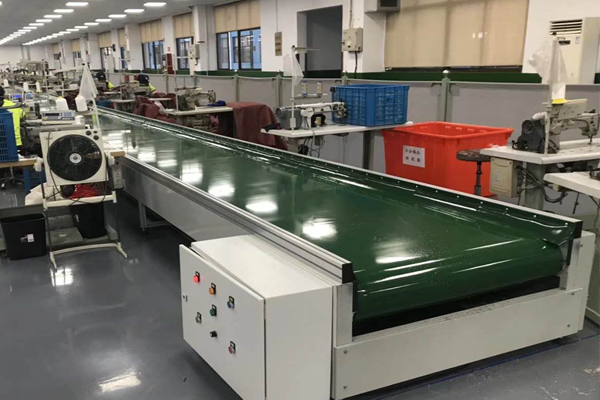

Teflon is renowned for its non-stick and anti-friction properties, making it an ideal material for conveyor belts. The Teflon conveyor belt is heat resistant, chemically inert, and low friction, allowing for efficient material handling in challenging environments.

The Teflon conveyor belt's high temperature resistance, up to 500 degrees Fahrenheit, makes it suitable for applications where heat is a factor such as drying ovens or powder coating lines. Its non-stick surface prevents materials from sticking or building up on the belt, ensuring a consistent flow of materials. This attribute also means easier cleaning since residue can be wiped away without difficulty.

With excellent release properties, the Teflon conveyor belt is an optimal choice for processing sticky or tacky materials that typically adhere to regular belts. In the packaging industry, these belts convey items like melted cheese, sticky candies, or hot glue without issues. For industrial applications like assembly lines, the low friction belt reduces drag on items during transfer for more energy efficient operations.

Chemically resistant to nearly all substances, the conveyor belt withstands exposure to oils, chemicals, solvents, and corrosive fluids. It does not break down or degrade over time with exposure to harsh elements, making it suitable for demanding environments in industries such as chemical processing, pharmaceutical production, or mining. The belt's non-reactive and non-contaminating properties also make it ideal for clean room settings.

Overall, the unique qualities of the Teflon conveyor belt deliver distinct advantages over conventional belts. With its combination of release, temperature, chemical and friction properties, this versatile belt provides an advanced material handling solution suitable for a wide range of automated operations. The Teflon conveyor belt helps improve productivity, efficiency and safety for any environment where moving materials at high speeds is a requirement. This innovation proves useful across manufacturing, packaging, food processing, medical and various other industries.

Teflon conveyor belt

RELEVANT INFORMATION

7 installation tips for conveyor belts for coal mines

2022-07-01

524

Wire rope conveyor belt electric peeling machine

2022-07-01

24

What are the advantages of using flame retardant conveyor belts?

2022-07-01

75