Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

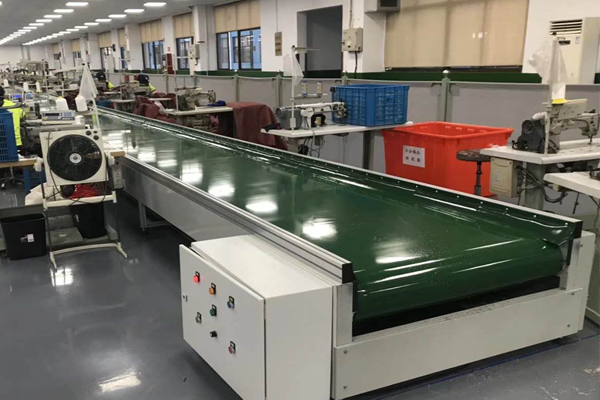

Application areas of conveyor belts

2022-07-21

75

Conveyor belt belongs to the belt category, as the name implies, is used to convey materials, such as conveying materials passed on the assembly line. Conveyor belts are widely used in mining, cement, coking, metallurgy, chemical, steel and other industries where the conveying distance is short and the conveying volume is small. Today Shandong coal mine conveyor belt manufacturer will explain to you the 7 installation tips of coal mine conveyor belt!

1、Put on a rolling sensitive shaft on the core of the conveyor belt, and set up the belt roll, and pay attention to the direction of the upper and lower cover rubber before setting up the shelf not to set up the opposite.

2、In the workplace where it is not suitable for the shelf, the conveyor belt roll can be guided away and the belt at the fold has a large enough radius of curvature to avoid damage to the conveyor belt, and stop placing heavy objects on the belt at the fold.

3、If the conveyor belt is to be replaced, the new belt can be connected with the old one, and the unloading and installation of the new belt can be carried out together.

4、On the horizontal working conveyor, the old conveyor can be cut off at any point, and the conveyor working in skewed direction, it is necessary to choose a good cutting point to avoid sliding and losing control due to self-weight.

5、After putting the new belt in the right position in the conveyor big, fix one end of the tape with the fixture, then connect it with the rope that goes around the roller and the pulley, and rack the conveyor belt to the conveyor in a balanced way through the traction installation, when traction, avoid the conveyor belt and rack to squeeze each other.

6、Fix one end of the conveyor belt on the conveyor frame with the fixture, and pull the other end tightly through the pulley until the conveyor belt has no significant sag on the return roller.

7、Fix the tensioning installation 100~150mm from the starting point.

installation ,belt,small.

RELEVANT INFORMATION

7 installation tips for conveyor belts for coal mines

2022-07-01

524

Wire rope conveyor belt electric peeling machine

2022-07-01

24

What are the advantages of using flame retardant conveyor belts?

2022-07-01

75