Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Analysis of the causes of aging of conveyor belt rubber

2022-07-21

84

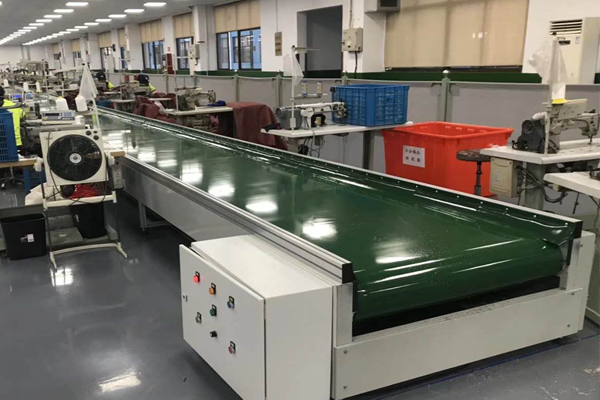

Those who use conveyor belts know that the raw material of conveyor belts is rubber, and rubber aging is a problem often encountered in the processing, storage and use of rubber and its products (conveyor belts). As a professional rubber conveyor belt manufacturer, Hengda has accumulated a lot of knowledge and experience in decades of production, and the reasons for rubber aging of conveyor belts are analyzed as follows.

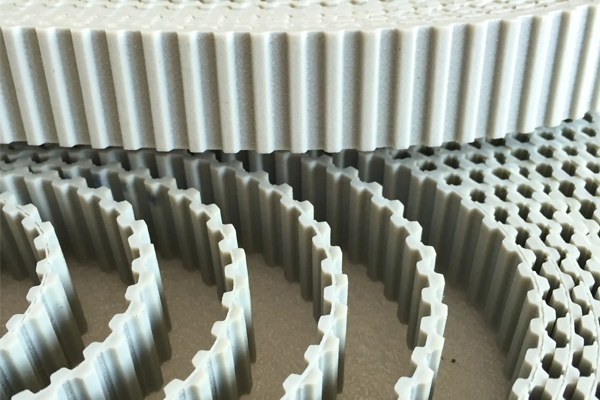

The so-called rubber aging is actually the surface of the conveyor belt manifested as cracking, sticky, hardening, softening, chalking, discoloration, long mold and so on. The factors that cause rubber aging are the following five aspects.

1, oxygen, oxygen in the rubber with the rubber molecules free base chain lock reaction, molecular chain breakage or excessive cross-linking, causing changes in rubber properties. The role of oxygen is one of the important reasons for the aging of rubber.

2, heat, raise the temperature can cause thermal cracking or thermal crosslinking of rubber conveyor belt rubber. But the basic role of heat or activation. Increase the rate of oxygen diffusion and activation of the oxidation reaction, thus accelerating the rate of rubber oxidation reaction, which is a widespread aging phenomenon - thermal oxygen aging.

3、Mechanical stress, under the repeated action of mechanical stress, will make the rubber molecular chain cleavage to generate free Tsuen, triggering the oxidation chain reaction, forming a force chemical process. Mechanical breakage of molecular chains and mechanical activation of the oxidation process. Which can be dominant, depending on the conditions in which they are located. In addition, under the action of stress easily caused by ozone cracking.

4, moisture, the role of moisture has two aspects: rubber in the humid air drenching or immersion in water, easy to destroy, this is due to the water-soluble qualities of rubber and clear water TWG and other components are water extraction dissolution, hydrolysis or absorption and other reasons caused by. Especially under the alternating effect of water immersion and atmospheric exposure, it will accelerate the destruction of rubber. But in some cases the water on the rubber does not play a destructive role, and even has the effect of delaying aging.

5, light, the shorter the light wave, the greater the energy. The destructive effect on rubber is the higher energy of ultraviolet light. In addition to UV light can directly cause the breakage and cross-linking of rubber molecular chains, rubber due to the absorption of light energy and free radicals, triggering and accelerating the oxidation chain reaction process. Ultraviolet light plays a heating role. Another characteristic of the light action (different from the thermal action) is that it is mainly generated on the surface of the rubber. Specimens with high rubber content will have web-like cracks on both sides, which is called "light outer layer crack".

The above five points are the experience summed up by Shandong coal mine conveyor belt manufacturer Hengda conveyor belt in the long-term production and sales, I hope you can effectively pay attention to prevention in the storage process to avoid unnecessary losses!

manufacturer,experience,accumulated

RELEVANT INFORMATION

7 installation tips for conveyor belts for coal mines

2022-07-01

524

Wire rope conveyor belt electric peeling machine

2022-07-01

24

What are the advantages of using flame retardant conveyor belts?

2022-07-01

75