Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Enhancing Productivity with Climbing Conveyor Belts in Industrial Settings

2023-08-03

1. Introduction: Climbing Conveyor Belts for Enhanced Productivity

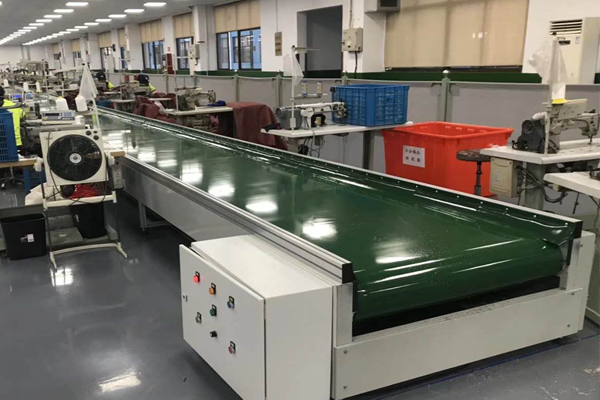

In today's fast-paced industrial landscape, maximizing productivity is crucial for staying competitive. One innovative solution that has gained popularity is the use of climbing conveyor belts. These versatile systems offer numerous benefits that can significantly enhance efficiency in various industrial settings. This article explores the advantages, applications, considerations, and maintenance guidelines associated with climbing conveyor belts.

2. Understanding Climbing Conveyor Belts: How Do They Work?

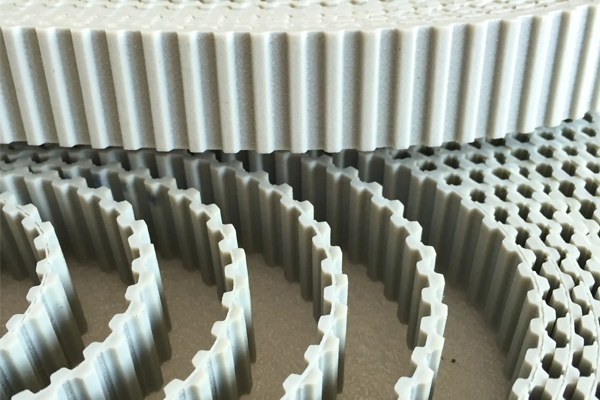

Climbing conveyor belts, also known as inclined or vertical conveyors, are designed to transport materials vertically or at an incline. Unlike traditional horizontal conveyors, climbing conveyor belts utilize specialized mechanisms to move products from one level to another. These mechanisms may include cleats, attachments, or adjustable belt angles to ensure a smooth and controlled ascent.

3. Benefits of Climbing Conveyor Belts in Industrial Settings

Implementing climbing conveyor belts in industrial settings brings a multitude of benefits. Firstly, they optimize space utilization by efficiently transporting materials vertically, making them ideal for factories with limited floor space. Additionally, climbing conveyor belts offer seamless integration into existing production lines, allowing for streamlined workflow and reduced manual labor.

Another key advantage is the ability to handle delicate or fragile items with utmost care. The controlled ascent of climbing conveyor belts prevents product damage and minimizes the risk of accidents during transportation. Moreover, with the right design and configuration, these conveyor belts can handle heavy loads, increasing overall productivity.

4. Applications of Climbing Conveyor Belts in Different Industries

Climbing conveyor belts find applications across various industries. In the manufacturing sector, they are commonly used for vertical transportation of components, materials, and finished products. In warehouses, these conveyor belts efficiently move goods between different levels, optimizing order fulfillment processes.

The food and beverage industry benefits from climbing conveyor belts by facilitating the vertical movement of ingredients, packaging materials, and finished products. In the automotive sector, these conveyor belts streamline the assembly process by transporting parts to different levels.

5. Key Considerations for Choosing Climbing Conveyor Belts

When selecting climbing conveyor belts for industrial applications, several factors need to be considered. It is essential to assess the required capacity, belt width, speed, and inclination angle to ensure optimal performance. Additionally, the type of material being transported and its characteristics, such as weight, size, and fragility, should be taken into account.

Furthermore, considering the specific operational environment, such as temperature, humidity, and cleanliness requirements, is crucial for selecting the appropriate belt material and construction. Consulting with experts or conveyor system manufacturers can provide valuable guidance in choosing the most suitable climbing conveyor belt for your unique needs.

6. Maintenance and Safety Guidelines for Climbing Conveyor Belts

To ensure the longevity and safe operation of climbing conveyor belts, regular maintenance is essential. This includes routine inspections of the belt, cleaning, and lubrication of moving parts, and timely replacement of worn components. Proper training of operators on safety protocols and emergency procedures is also vital to minimize the risk of accidents.

Implementing preventive maintenance measures, such as scheduled inspections and proactive repairs, can prevent unexpected breakdowns and increase the overall reliability of climbing conveyor belts. Following manufacturer guidelines and industry best practices will help maintain optimal performance and ensure a safe working environment.

7. Frequently Asked Questions (FAQs)

8. Conclusion

Climbing conveyor belts offer a valuable solution to enhance productivity in industrial settings. Their ability to transport materials vertically or at an incline optimizes space utilization and streamlines workflow efficiency. With their numerous benefits, climbing conveyor belts find applications in various industries, allowing for the safe and efficient movement of components, products, and materials.

By carefully considering key factors such as capacity, belt width, material characteristics, and operational environment, businesses can select the most suitable climbing conveyor belt system for their specific needs. Regular maintenance and adherence to safety guidelines ensure the reliable operation of climbing conveyor belts, contributing to increased productivity and a safer working environment.

Incorporating climbing conveyor belts into industrial processes can revolutionize productivity, making them an invaluable asset in today's competitive market. Embracing this innovative technology empowers businesses to optimize their workflow, reduce manual labor, and maximize overall efficiency.

climbing conveyor belt

RELEVANT INFORMATION

7 installation tips for conveyor belts for coal mines

2022-07-01

524

Wire rope conveyor belt electric peeling machine

2022-07-01

24

What are the advantages of using flame retardant conveyor belts?

2022-07-01

75